Wood, glass, gypsum

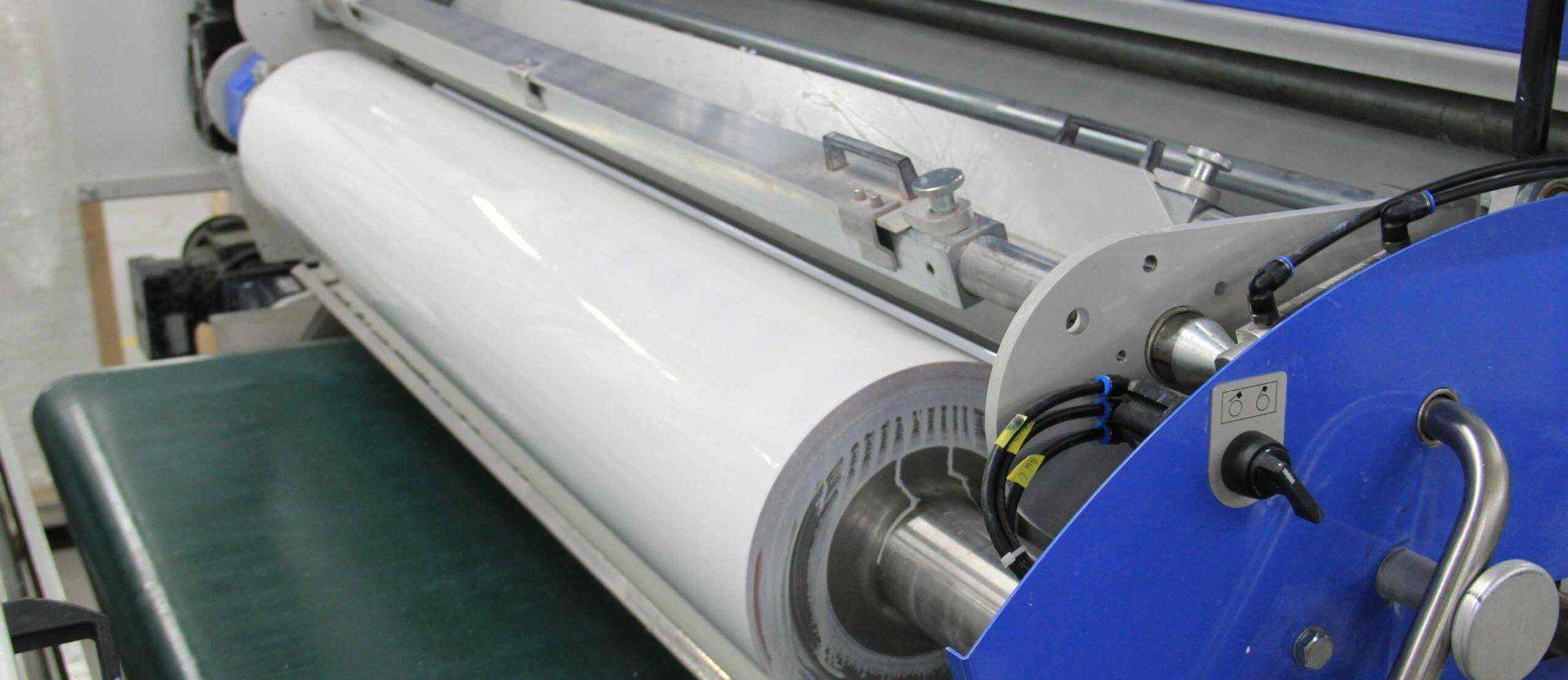

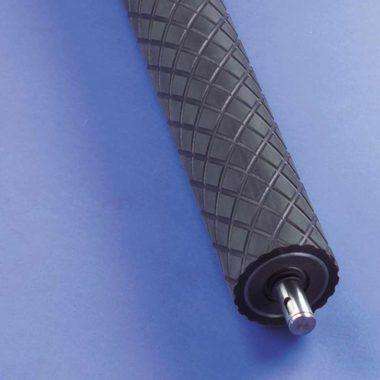

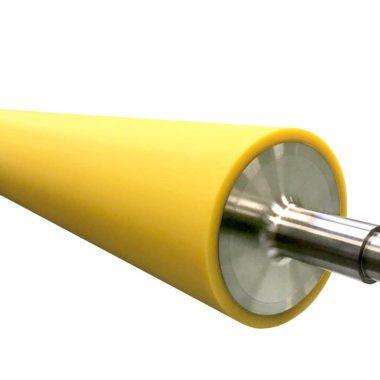

[PUR] moves boards and sheets! Thanks to their exceptional properties, polyurethane materials have long since been used in machines for processing wood, gypsum and glass. Above all, polyurethane’s resistance to solvents, adhesives, fuels, mineral oils, paints and greases, the extremely variable hardness range from 20 to 95 Shore A and the significantly better service life compared with rubber have made it ideal for conveying sheets, boards and panes.

Our [PUR] Intec CI and HI blends have made a name for themselves for paint application rollers in particular. With their very low surface roughness and excellent resistance to swelling when in contact with paints and solvents, our cylinders ensure outstanding application performance. We would be happy to recoat your old cylinders. Upon request, Internorm can supply complete cylinders with new cores. Put us to the test!

Our Internorm [PUR] Intec E material is the right choice for handling sharp-edged panes of glass or abrasive gypsum and concrete boards. With an abrasion resistance of < 15mm3, we give you a plastic material that is really long-lasting, even under difficult conditions.

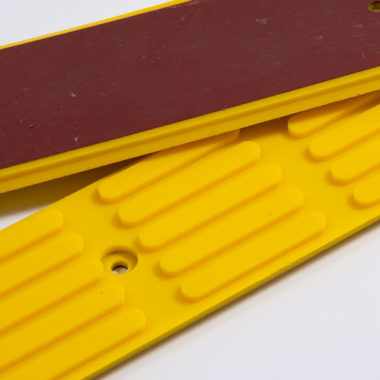

We supply cylinder coatings, coated plates for conveyor chains, crawler track shoes, sealing membranes and engineered plastic parts to customer specification.

We use polyurethane, silicone, rubber and sponge rubber compositions in all grades. Cores or other metal items can be supplied as well.

Examples of applications

The [PUR]e focus on development and production

INJECTIONMOULDING

Are you looking for a specialist to manufacture your injection-moulded parts? Then take a look here.

[PUR]CASTING

Do you need large, soft or elastic parts made from polyurethane? Then simply get in touch with us!

[PUR]CYLINDERS

Here are some examples of cylinders with [PUR] coatings. Take advantage of our all-round service.