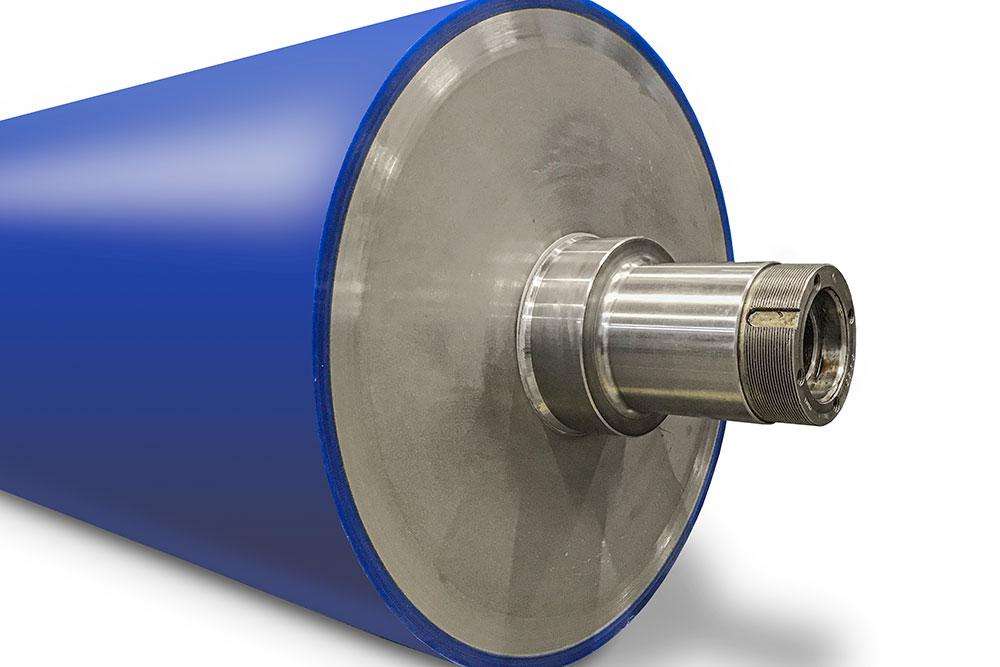

Cylinder coating PUR

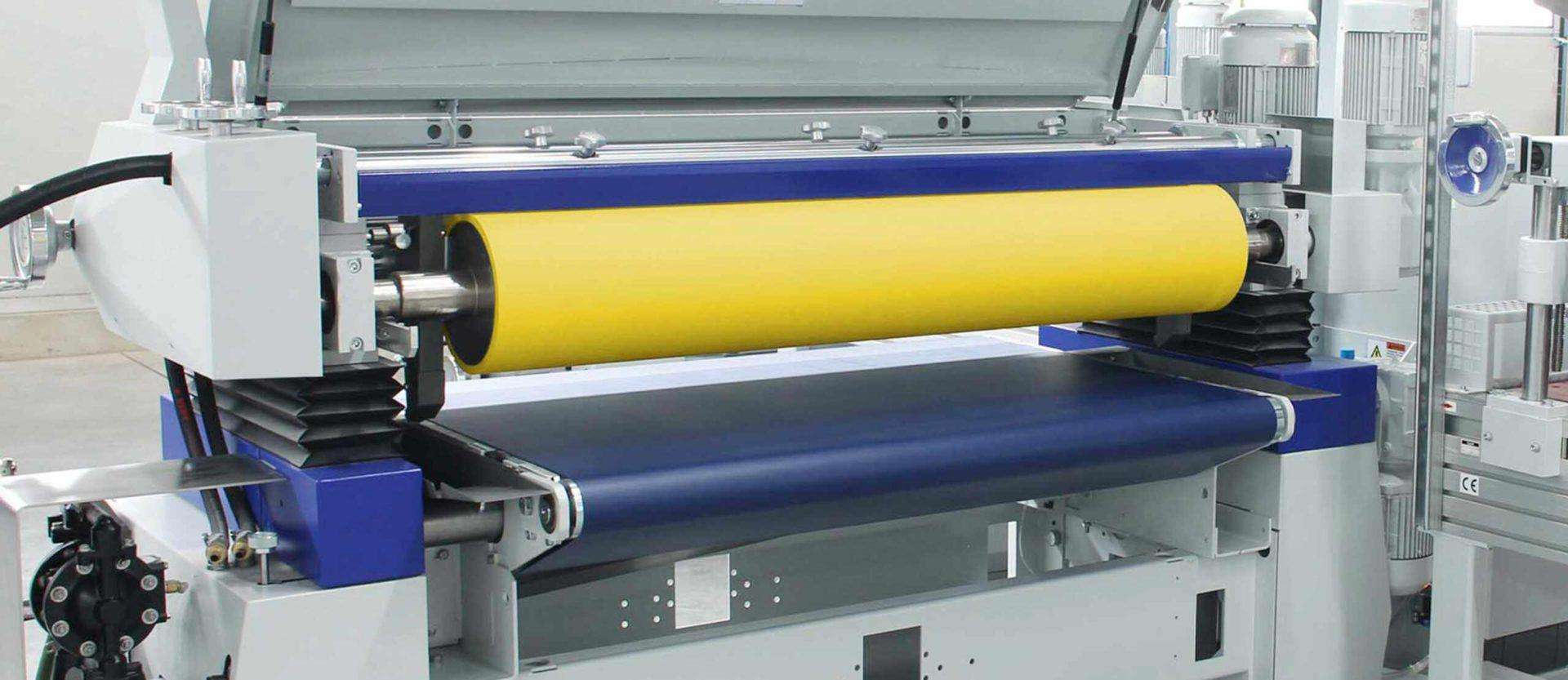

Cylinders with elastomer-based plastic coatings are used for numerous applications in the paper, wood, steel, sheet metal, printing, mining, agricultural and textile industries. And in general machine applications too, cylinders are required for conveying, feeding or generating a contact pressure.

At INTERNORM we use polyurethanes for coating cylinders. The selection of the correct material depends on the cylinder specification. Polyurethanes are chosen when high demands are placed on service life, wear and abrasion resistance, behaviour under dynamic stresses and chemical resistance.

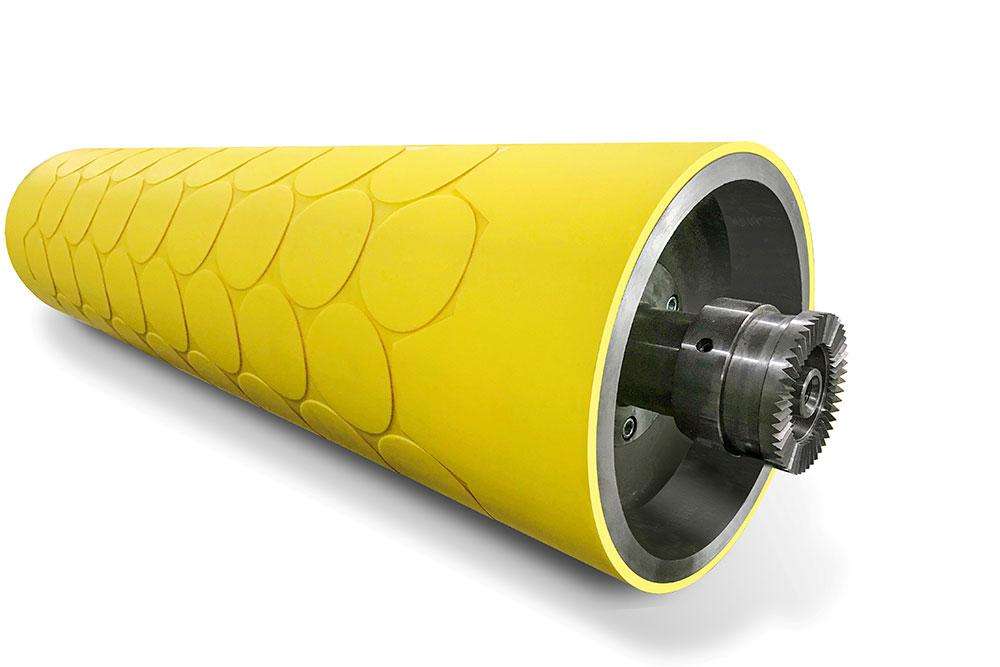

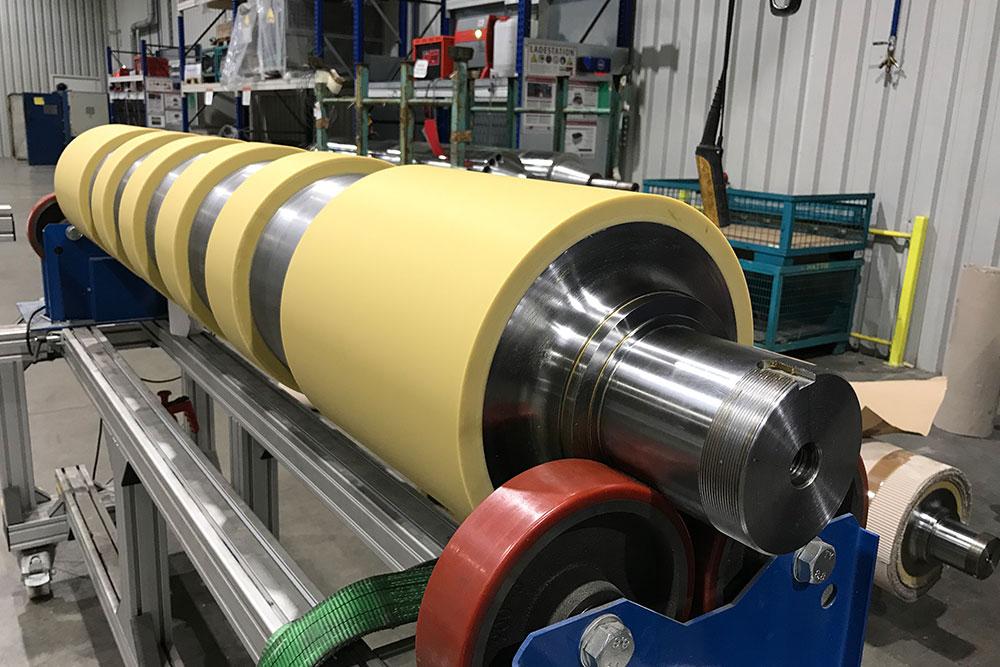

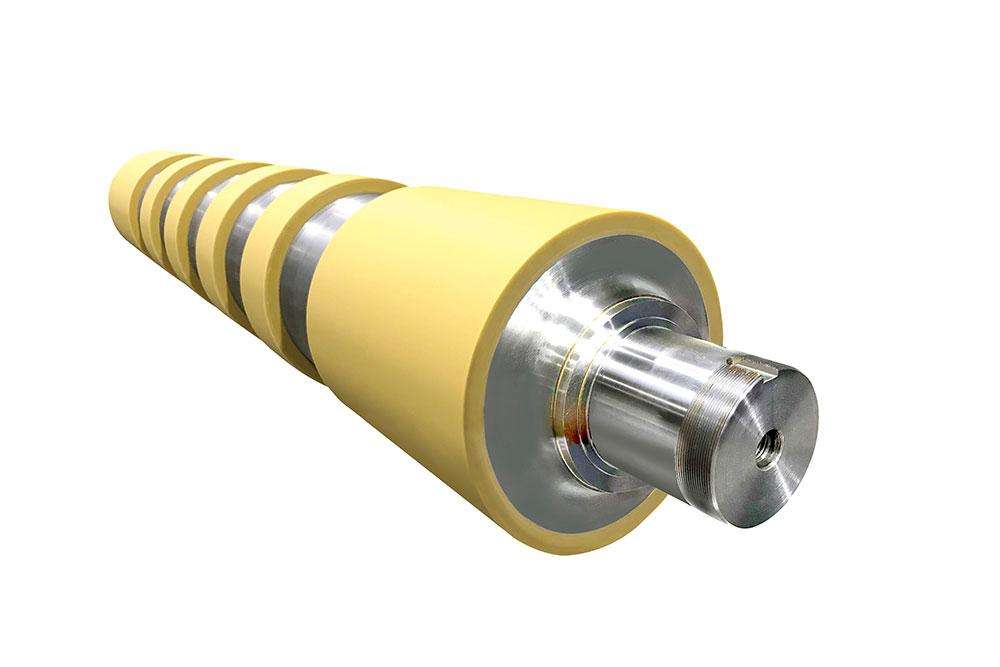

Rotational moulding – fast, efficient and for large cylinders.

The advantages of rotational moulding are obvious: watch the video – there’s no faster way of coating cylinders!

- No moulding – and hence no mouldmaking and mould costs

- Low material wastage thanks to a small overbuild

- Short production time (no preheating, no moulding, no demoulding)

- Multi-module coating – sandwich systems possible

- Thick coatings of 30 mm and more in one pass

- Hardness values from 60° to 90° Shore A with rotational moulding

Of course, the material has the excellent properties of a polyurethane ether with improved hydrolysis resistance and resistance to chemicals.

[PUR] is not the only trump card here

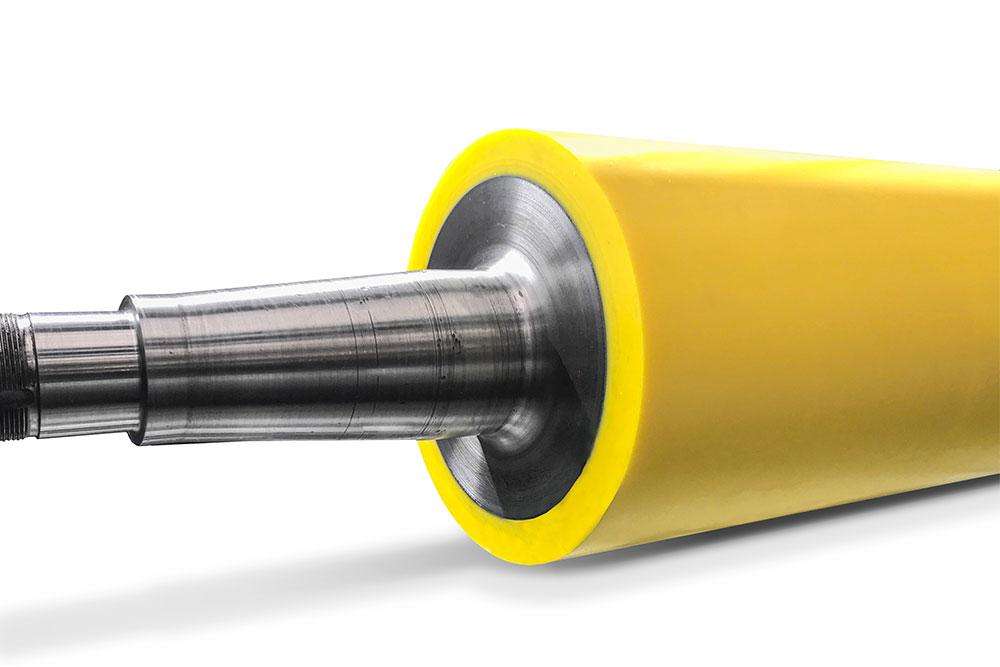

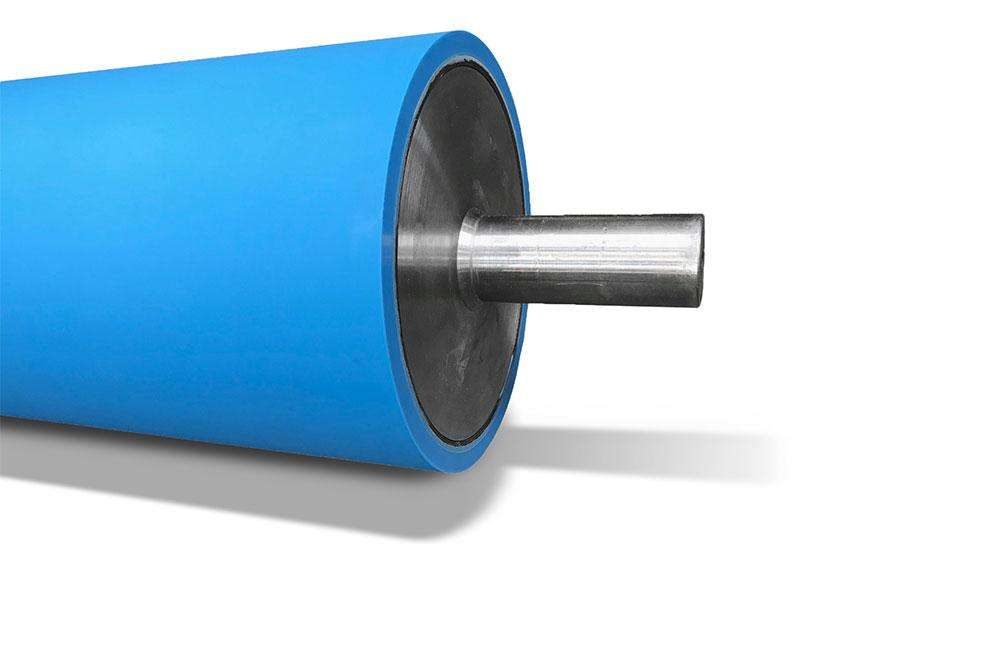

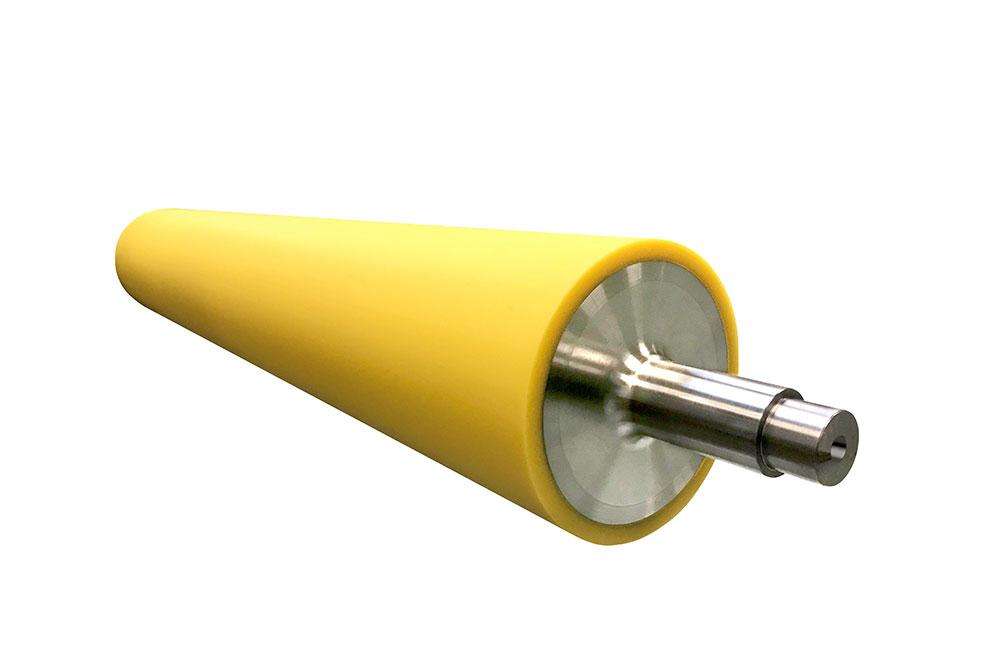

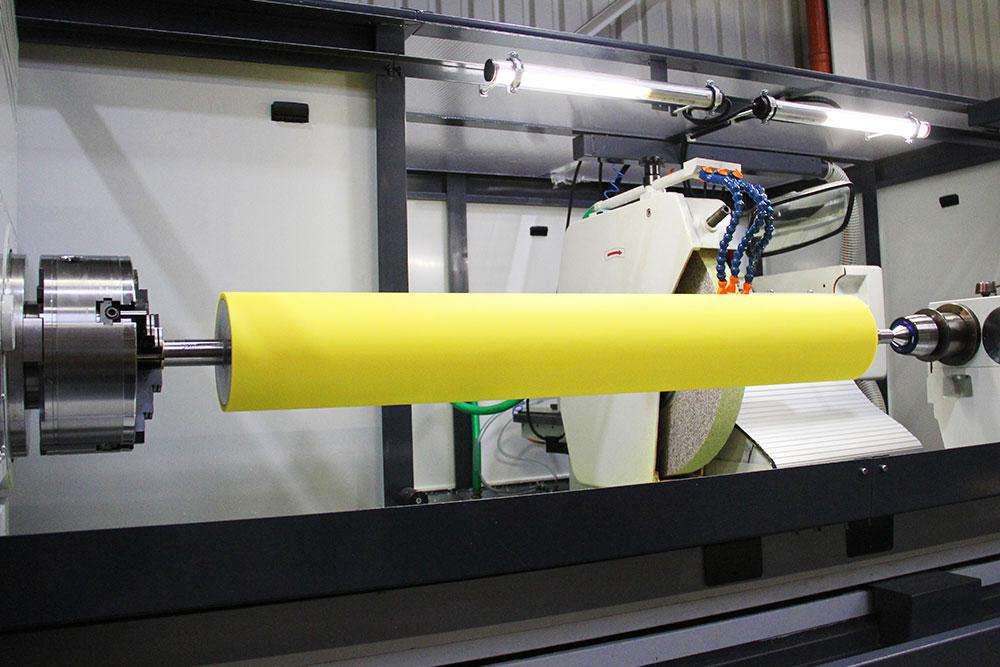

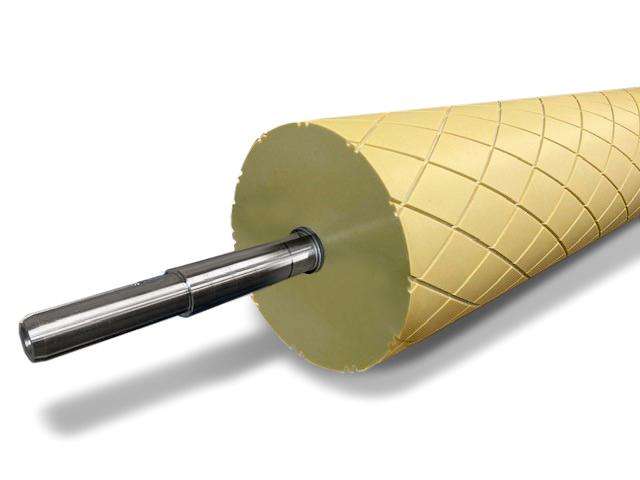

CASTING OF CYLINDERS – SOFT, ELASTIC AND SIMPLY LONGER-LASTING

When it comes to cylinders, we distinguish between hot and cold casting. Casting takes place in suitable moulds. The materials can be used for many applications and exhibit excellent mechanical properties. We can supply materials made from PUR with hardness values from 20° Shore A to 70° Shore D. The cylinders can be ground, turned with profiles or even laser-engraved. Simply ask our cylinder experts!

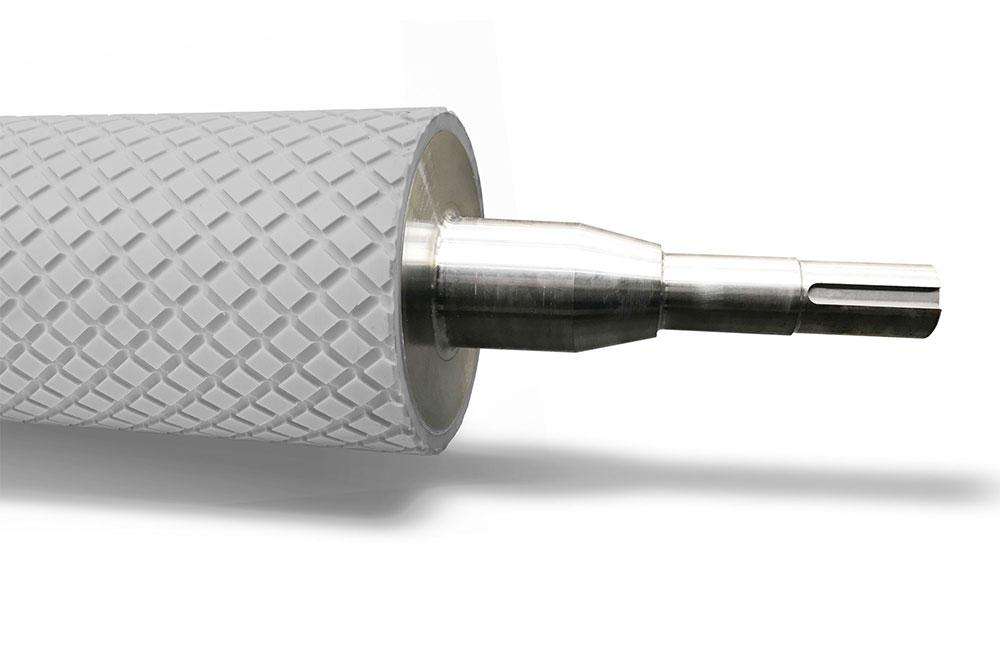

RUBBER CYLINDERS AND ROLLERS WITH A SILICONE COATING – RESISTANT TO MANY CHEMICALS

Where grip and resistance to chemicals are required, EPDM and Hypalon cylinders are the best choices.

The chemical and mechanical properties of these rubber blends are optimised by mixing in specific additives. Internorm therefore has the right blend for almost every application.

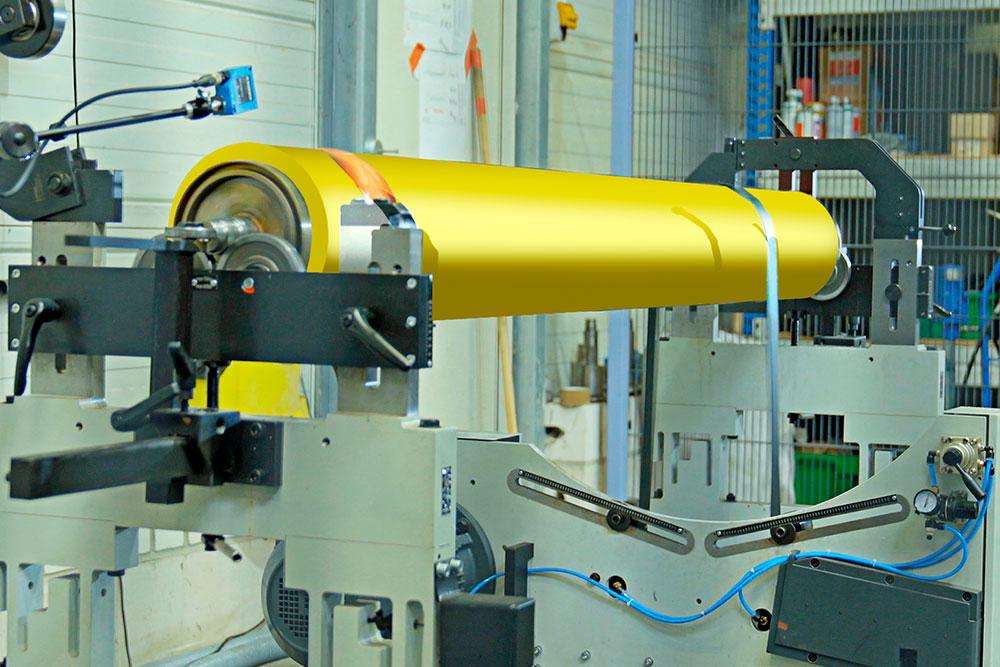

PAINT APPLICATION ROLLERS – WHERE POLYURETHANE IS THE FIRST CHOICE

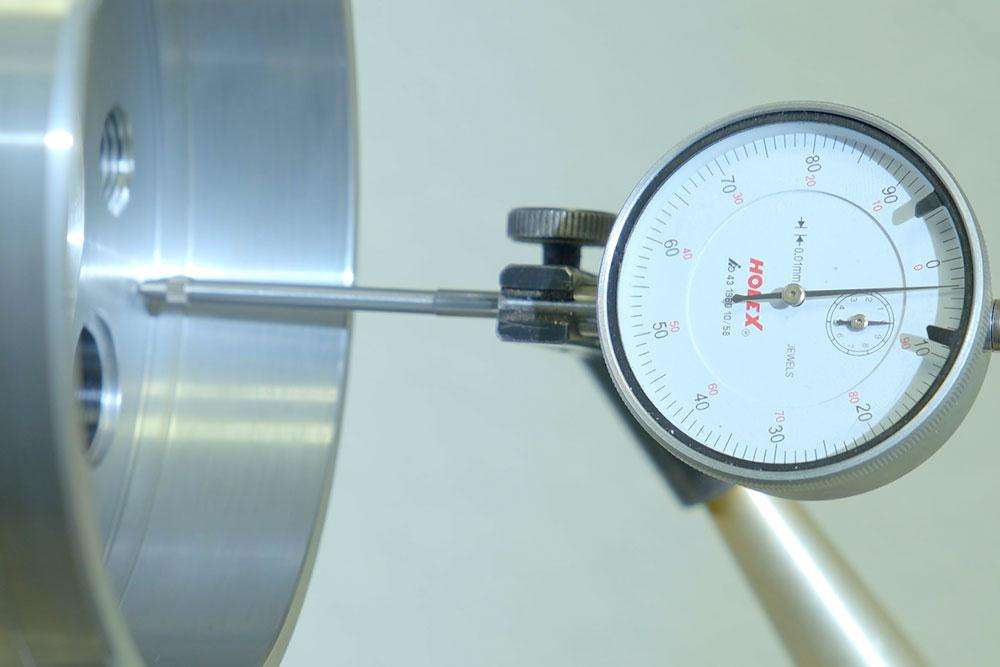

With our excellent Intec CI material, Internorm is one of the leading paint application roller manufacturers in Germany. Whether for applications in the woodworking, metalworking or metal packaging industries, Internorm paint application rollers are almost always the best choice. We can supply hardness values from 20° to 70° Shore A and surface finishes as fine as Ra = 0.4 µm.

We are happy to recoat your cylinders, too. Complete cylinders with core and case are our speciality. Simply get in touch with us. We will be happy to help you!

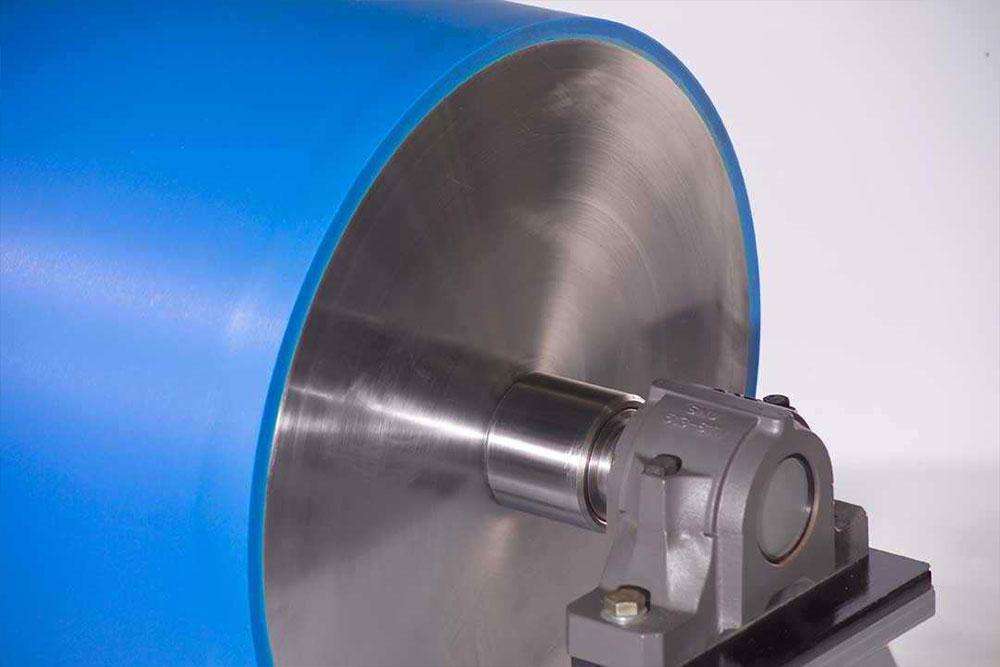

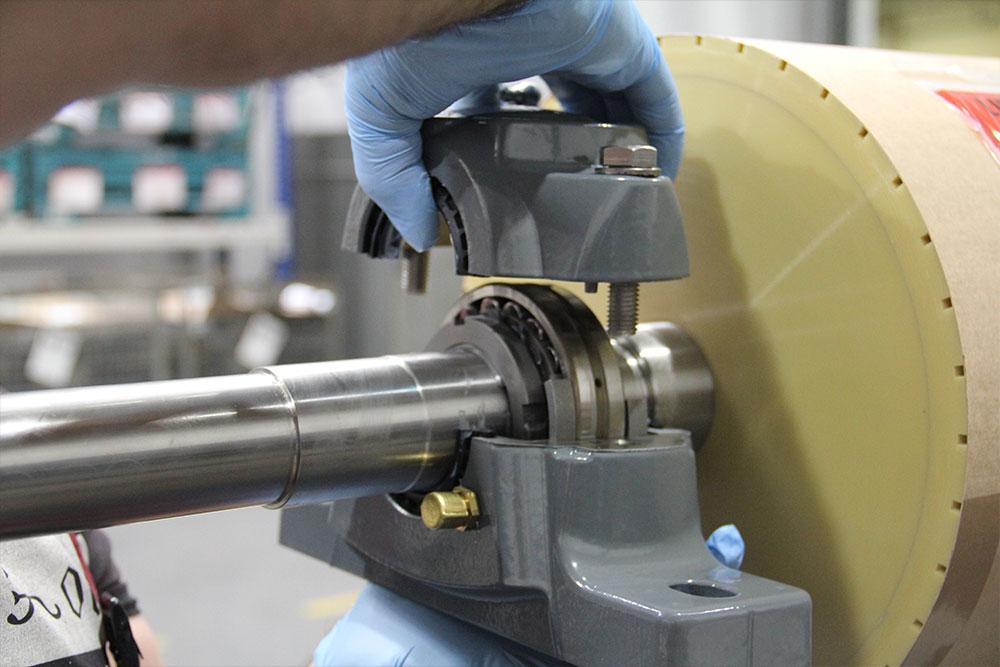

MOUNTED CYLINDERS – TAKE ADVANTAGE OF OUR SERVICE

Thanks to our connection with Grimme, a manufacturer of agricultural machinery with more than 3.100 employees, we have very good, cost-effective access to machine components such as ball bearings and housings plus lubricants and seals. Take advantage of our engineering expertise and order complete ready-to-install units from Internorm!

RIBBON-FLOW MOULDING – FAST, EFFICIENT AND FOR LARGE CYLINDERS

The advantages of ribbon-flow moulding are obvious: Watch the video – there’s no faster way to coat cylinders!

– No moulding – and hence no mouldmaking or mould costs

– Low material wastage thanks to a small overbuild

– Short production time (no moulding/demoulding)

– Multi-module coating – sandwich systems possible

– Thick coatings of 30 mm and more in one pass

– Hardness values from 65 to 90 Shore A with ribbon-flow moulding

The material has the excellent properties of a polyurethane ether with improved hydrolysis resistance and resistance to chemicals.

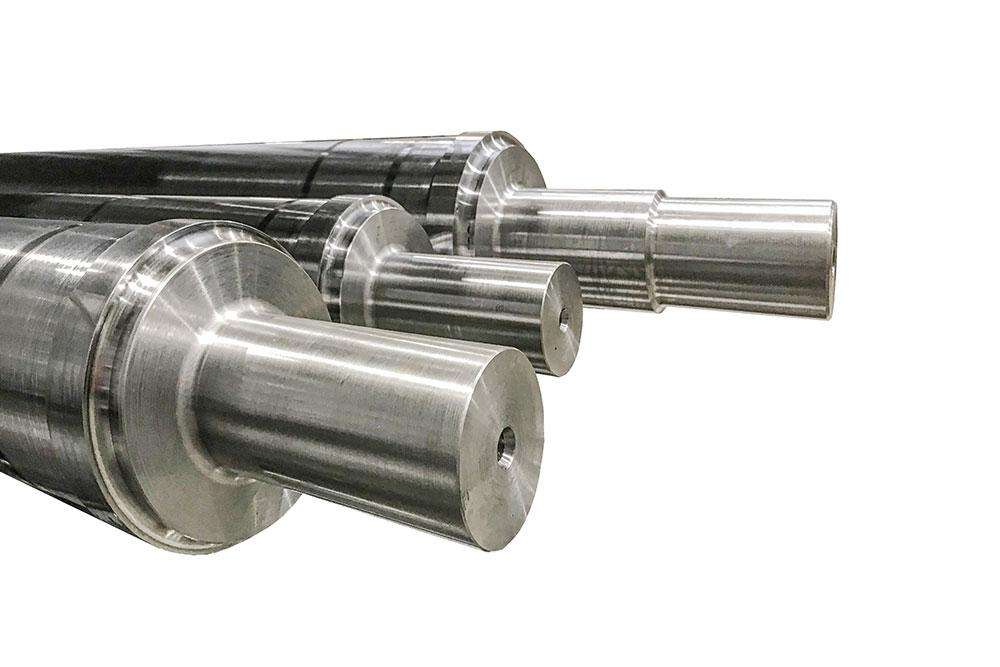

CYLINDER CORES – WHETHER STAINLESS STEEL, ALUMINIUM OR STEEL – SUPPLIED COMPLETE WITH YOUR CORE!

You can get a complete cylinder from us. All from one supplier, without you having to deal with the core separately. Take advantage of our many years of experience. Whether laser-welded, friction-welded, forged or shrink-fit, we offer all conceivable manufacturing procedures. In stainless steel, aluminium or other materials. One provider, one contact, Internorm!